Key Takeaways

- Understand the role of configuration solutions in modern manufacturing.

- Explore the benefits of adopting innovative technologies in product configuration.

- Determine possible obstacles and ways to get past them.

The Manufacturing Landscape Today

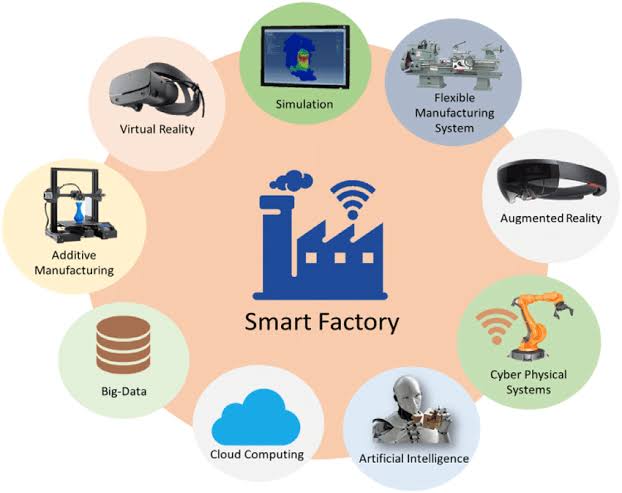

The manufacturing landscape has evolved significantly in recent years, with technological advancements and automation reshaping how products are designed, produced, and delivered. Businesses frequently adopt smart manufacturing solutions to increase productivity, cut waste, and improve product quality. Innovations like the Internet of Things (IoT) and advanced robotics have made it easier for manufacturers to monitor operations in real-time, ensuring optimal performance and quick adjustments to changing demands. These technologies streamline workflows and create more intelligent, responsive supply chains.

A vital aspect of this transformation is using Configure, Price, Quote (CPQ) software, which enables manufacturers to quickly generate accurate quotes and customize product configurations based on customer specifications. By automating the configuration and pricing process, CPQ software reduces errors, shortens lead times, and enhances customer satisfaction. This software integration simplifies the sales process and aligns production with customer needs, leading to more streamlined manufacturing operations.

What Are Configuration Solutions?

Configuration solutions represent a crucial advancement in the manufacturing process. They are sophisticated software platforms designed to streamline customization, reduce manual intervention, and ensure high precision in product development. These systems assume the burden of complex calculations and decision-making, freeing human resources for more strategic tasks.

The primary advantage of configuration solutions lies in their ability to deliver tailored products efficiently. The dynamic nature of these systems allows manufacturers to adjust product specifications in real time, directly aligning with customer preferences. Observable commercial benefits from this flexibility include reduced production costs and faster time to market. The value proposition of configuration solutions is straightforward. They enable producers to enhance customization levels without suffering from the typical drop in output.

- Customization: Configuration solutions facilitate the precise customization of products, enabling manufacturers to meet the unique requirements of various clients seamlessly. This capability is critical in today’s market, where consumer expectations for personalized experiences are high.

- Efficiency: Configuration solutions eliminate unnecessary manual processes through automation, significantly reducing the time from order placement to product delivery. This automation is essential for maintaining competitiveness in a fast-moving commercial environment.

- Accuracy: By minimizing human error, these systems enhance precision and consistency in production outcomes, safeguarding product quality and strengthening brand reputation.

Benefits of Smart Technology in Configuration

Integrating smart technology in configuration solutions significantly advances the manufacturing sector. These smart-systems provide a holistic approach to boosting operational efficiency, promoting accuracy, and elevating customer satisfaction. Manufacturers increasingly recognize the value of moving towards a digital-first approach, where innovative technology is central to transforming traditional processes.

For instance, businesses employing connected factory environments through the Internet of Things (IoT) technology report enhanced productivity and reduced operational downtimes. These environments utilize real-time data analytics to make informed decisions, optimize resource usage, and streamline production lines. This data-driven approach helps forecast demands accurately and manage inventory more efficiently, thus reducing waste and improving profit margins.

Furthermore, innovative technology in configuration enables a seamless flow of information across the manufacturing enterprise, fostering more transparent communication and vital collaboration among teams. By breaking down silos, businesses can enhance their capacity for innovation and respond more effectively to market changes. The advancement into smart configuration systems underscores a strategic move towards higher efficiency and standardized processes, paving the way for future-ready manufacturing models.

Challenges in Implementing Configuration Solutions

Despite their transformative potential, configuration solutions pose specific challenges that manufacturers must address to maximize their effectiveness. One primary concern is the significant initial investment required to acquire advanced software and integrate it with existing systems. Moreover, compatibility issues often arise during integration, particularly in organizations reliant on outdated legacy systems.

Additionally, the transition to new systems can impact workforce dynamics, necessitating extensive employee retraining to operate these systems proficiently. This investment in training is essential to reduce operational disruptions and ensure that employees can leverage the full capabilities of the new systems. Addressing these challenges proactively is crucial for businesses seeking to implement configuration solutions effectively and realize their long-term benefits.

Strategies for Overcoming Challenges

Companies can handle the difficulties of applying configuration solutions in several ways. A comprehensive needs analysis must be conducted to ensure that the selected solution meets the business’ particular requirements and capabilities. This procedure creates a clear implementation plan and assists in identifying possible gaps.

- Conducting a Needs Analysis: Understanding the specific operational requirements and challenges across various departments ensures that the chosen configuration solution effectively meets all critical needs, facilitating smoother integration.

- Comprehensive Training Programs: Implementing robust training initiatives empowers employees, enabling them to adapt swiftly to new systems and optimize their functional competencies thus reducing potential disruptions.

- Selecting Scalable Solutions: Opting for scalable configuration systems allows businesses to grow and adapt based on market demands, ensuring sustainability and relevance over the long term.

Starting with pilot projects offers a practical approach to testing configurations on a smaller scale, mitigating risks and allowing for refinement before full-scale deployment. This gradual scaling ensures systems are optimized for effectiveness and predictability, laying a solid foundation for ongoing innovation.

The Future of Manufacturing

The manufacturing sector is poised for an extraordinary transformation fueled by technological advancement. As emerging trends redefine industry standards, manufacturers with robust configuration solutions will be best positioned to adapt swiftly to the evolving market landscape. The future heralds a shift from traditional mass production towards more personalized and responsive manufacturing models, guided by the ever-growing demand for customer-centric solutions.

By investing in innovative technologies such as IoT and AI and comprehensive configuration solutions, businesses can secure a competitive edge while redefining the boundaries of manufacturing excellence. Numerous industry innovations illustrate that strategic adaptation to technological advancements will underpin future success. Organizations that embrace these changes proactively are likely to set new operational excellence and sustainability standards, ensuring their continued growth and leadership in the dynamic market landscape.